GETT has the widest range of glass keyboards.

And the variety of models is reflected in the range of applications you can use them for. They range from design-oriented environments to medical and hygiene-sensitive workplaces. Typing on glass is a totally different feeling to on the mechanical keys of a traditional PC keyboard.

When used as a keyboard surface material, glass offers benefits that are rarely found in other materials.

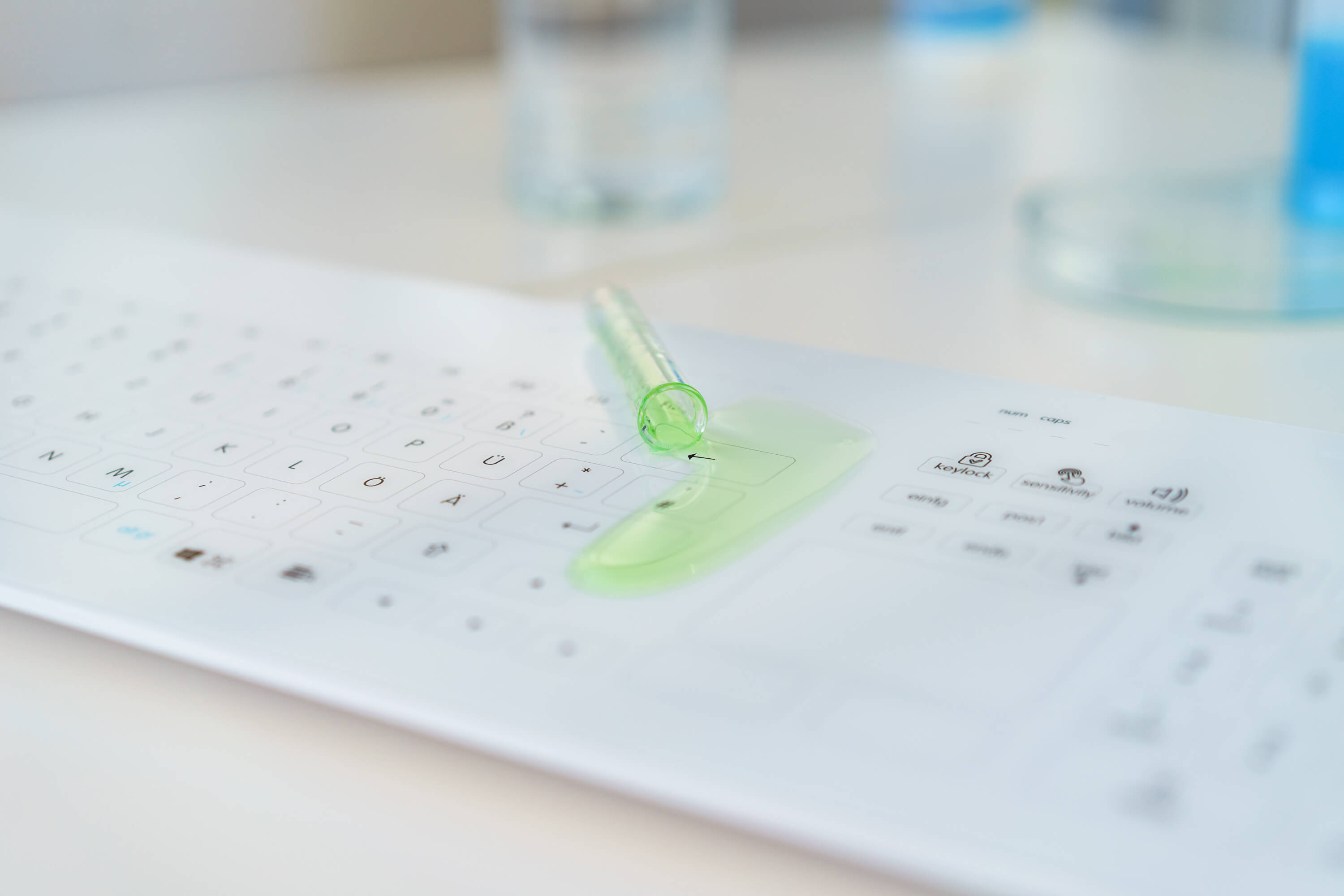

Hygiene.

Its flat, even, and sturdy surface makes glass perfect when hygiene and cleanliness are the order of the day. Removing grease, oils, bacteria, and germs is child’s play, and disinfectant can be used with virtually no limits.

Resistance.

Glass is surprisingly more durable when compared with other supposedly robust materials. It undergoes a hardening process to make it resistant to mechanical influences such as knocks or vibrations. It also hardly ages over times and can’t fall victim to corrosion.

Design.

Printing onto glass means that glass keyboards can feature a virtually unlimited range of designs. Apart from the keys and symbols that have to take a fixed position, it’s relatively easy to include free-form designs.

Inherent stability.

From a certain material thickness (2 millimetres for heat-toughened milk glass), glass has a high level of inherent stability and can therefore be used as both a user interface material and as a mechanical carrier medium.

First-time users may find it odd to type on a surface that is totally flat. But—hand on heart—who isn’t used to long and intensive use of their smartphone’s screen? And although smartphones use a different technology, projective-capacitive touchscreens, the principle remains the same. What does that mean exactly?

Fact 1.

Typing on a keyboard with a glass surface is physiologically better for wrists and fingers than using a traditional PC keyboard. By eliminating a mechanical stroke and the actuating force required to perform it, the entire motor system of the hand can be permanently relieved.

Fact 2.

The fact that the surface is sealed offers the user protection against dirt and therefore development of germ build-up. Simply wipe—and you’re safe and sound.

Fact 3.

You type with your eyes, too! Touch keyboards provide the aha effect and make the most-used office peripheral simply more stylish. It fits perfectly into premium, modern work environments and is a visual highlight instead of the standard dreariness.

Fact 4.

The keys of a mechanical keyboard have a defined actuating force and are therefore the same for each user. Touch keyboards make it possible to set the level of touch-sensitivity to attain a custom feel that suits you.

Fact 5.

General user preference is tending towards typing on glass keyboards, as the domination of the smartphone is influencing expectations. Just as the first glass keyboards were regarded with suspicion and hesitancy 15 years ago, today, they are accepted as a matter of course. And it’s not just digital natives who feel at home typing on their smartphones’ screen keypads, but those born into the analogue world. This is precisely what non-virtual touch keyboards facilitate—even large-format ones!

Fakt 6.

Der Nutzer profitiert von langlebiger Produktqualität „Made in Germany“. Die Produkte werden am Headquarter des Herstellers in der hauseigenen Manufaktur gefertigt. GETT achtet dabei auf hochwertige Komponenten, die die Tastaturen & Mäuse besonders robust machen. Im hauseigenen Prüflabor werden die Produkte Langlebigkeitstests unterzogen.

They began to creep into the public eye some 15 years ago as part of Apple’s smartphones—which gained them their first noteworthy market share. At the same time, and more as a trailblazer technology, the first glass desktop keyboards were also emerging. These offered the complete functionality of a traditional PC keyboard. At first not very popular, their popularity has experienced a continual rise since 2010, when people started realising that this technology didn’t just work, but it was also elegant and practical.

In technical jargon, glass used in operating devices including touch keyboards, is what is referred to as technical glass. Since the operating principle is based on the capacitive mode of action, requirements are primarily purely physical, so the glass must not contain metal structures or air gaps like safety or thermal glass. Untreated glass is equally unsuitable as it’s simply not strong enough. Depending on the product version and application area, the material is selected in different thicknesses and having undergone different processes.

Touch keyboards used and built in commercial industrial applications use a strong glass front of generally three millimetres to stand up to the rugged requirements of the environment. It is generally also hardened, using warming and cooling processes to create artificial tensions to achieve high impact, bending, and scratch resistance as well as thermal shock resistance. Touch keyboards used in PC workstations use an ultra-thin layer of glass, just as in a smartphone. Chemical hardening, achieved through an ionic exchange process, lends the glass high compressive strength on its surface, making it much less fragile than untreated glass. Gorilla Glass is one of the most well-known brands of this type of glass.

Concave keys.

Special grinding processes enable the glass thickness to be worn down at certain points. It is also possible to add virtually any type of circle, ellipsis, or rectangle.

Anti-reflective coating.

A chemical process makes the glass surface non-glare, reducing the amount of light reflected back, creating a “dull” finish.

Satin finish.

The satin finish means that translucent areas can be raised to the touch. This makes it possible for fingers to orient themselves with special haptic areas such as special keys and the touch pad among others.