Smart planning with CAD and the like.

Constructing and planning the interior furnishings for his own four walls—this was the lifelong dream of Daniel Möglich, consultant at Bechtle’s PLM-specialist DPS Software and master carpenter. No sooner said than done, the kitchen, bathroom and the staircase were all designed and planned with the SWOOD solution and final measurements were taken with a 3D laser measuring system. In this interview the house builder gives us insights into his very own digitalisation project.

Written by

Where did the inspiration come from to design your house with SWOOD?

Daniel Möglich – I know the software very well because I consult on it and support customers using it, from carpenters’ workshops to shop builders. I knew from the get-go that I wanted to design my own furniture and build it with SWOOD. I wanted the kitchen to be something special that you can’t get from a furniture store.

What materials do you like to work with?

That’s easy—wood. Processing, opportunities, its smell—there is so much freedom to build whatever you want. And that’s what fascinates me as a carpenter. Then there’s the fact that wood is renewable. Even its waste product can be used. This makes wood sustainable. In the meantime, the trade has changed a lot to using other materials such as glass, copper and Corian.

What was your planning process?

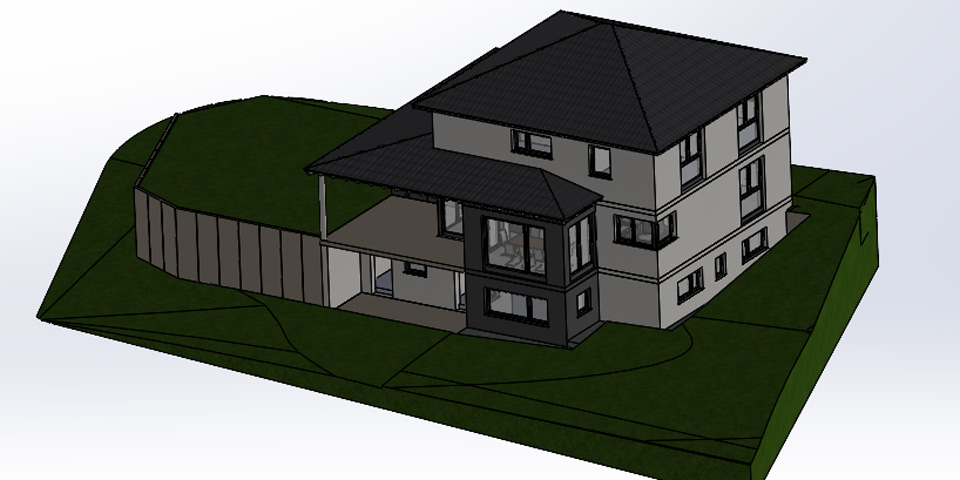

After deciding to build a house, I measured the perimeter of my plot of land with a large tape measure and created an outline in SOLIDWORKS. I then drew different house shapes in SOLIDWORKS and tried them out on the land digitally. After talking to our architect and playing the ideas back and forth, we created what became the latest draft. This is what I brought to the construction company to ask for offers.

How can SWOOD help you realise your house construction project?

SWOOD primarily helped me with the construction of the furniture (kitchen, bathroom and the staircase). I started out by creating a planning draft(water, sewage, electricity) then, after measuring with the 3D measuring system Flexijet, I was able to adjust the layout to the final measurements. One huge advantage was that I could finish the kitchen with all its details without knowing the exact dimensions from the building site.

SWOOD and Flexijet 3D.

SWOOD is a software that is fully integrated into the 3D solution SOLIDWORKS for companies working with wood and is specially aimed at carpenters, joiners, designers and interior designers with a focus on craftmanship, but also suitable for industrial shopfitters.

With Flexijet 3D, the portable 3D laser measurement system, measuring rooms, including windows, ceiling lamps etc. is child’s play. Measured elements such as walls, doors, arches or the entire room are rendered as a precise 3D CAD drawing on-site and in parallel to the measuring, making any reworking a thing of the past.

You measured the plot of land and the kitchen with Flexijet 3D. How exactly did you do this?

In order to estimate the exact elevation profile of the land, I measured it with Flexijet. I then imported the data into SOLIDWORKS and created a model of the site. After the walls had been plastered and the tiles had been laid, I used Flexijet to measure the most important points in the kitchen. The advantage here is that I can see directly what was measured on the screen, because the CAD model is built in front of your eyes.

So what are the next steps in your house construction project?

We’re on the final stretch. The furniture is made and I’ve already installed the kitchen. Since I constructed everything in SWOOD, the CNC programs had already run through, so I could send everything directly to the machine. My bathroom furniture is being constructed in parallel. This furniture too is bespoke, made in SWOOD, which gives it a personal touch. I even built in a laundry chute into the cabinet. Once the furniture is delivered from the workshop I will install it myself—a carpenter’s job.